SERVICES

Integrated solutions engineered to meet the highest quality and performance standards - combining technical innovation with durability to ensure superior production efficiency across industrial sectors.

Premium Products

Screening Systems

We provide cutting-edge technological solutions in industrial screening, engineered to the highest global quality standards to meet the needs of diverse industrial sectors.

A screening machine that uses a gentle, rotary motion similar to hand sieving, providing high accuracy while preserving the integrity of fragile materials. The tumbler screener separates fine materials ranging from 20 microns up to 10 mm through a gentle tumbling motion, ensuring high-precision classification.

The tumbler screener is used for:

solid materials, granules, and powders.

Advantages:

Up to 99% separation efficiency, low energy consumption, and the option of multi-deck screening.

Applications:

Widely used in food, pharmaceutical, chemical, and other fine material industries

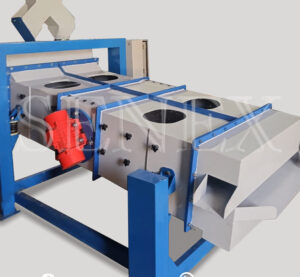

A vibrating unit with linear motion (forward–backward) used for material separation by size. It offers high precision in separating light materials with irregular particle sizes.

Suitable Materials:

Plastic flakes, powders, rubber granules.

Applications:

Food industry – Chemicals – Building materials – Pharmaceuticals – Metals.

A perforated cylindrical screen used for material separation and size-based filtration.

Key Features:

- Durable construction

- Easy maintenance

- Suitable for various industrial applications

- Higher production capacity compared to other separation equipment

Applications:

Recycling – Waste treatment – Mining – Sand and gravel separation

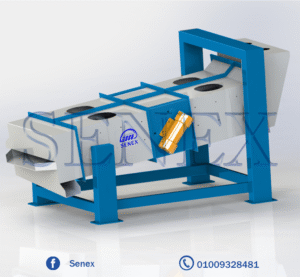

A vibrating feeder ensures continuous and uniform transfer of materials to production lines, increasing operational efficiency. It can also be used in washing and drying processes.

The vibrating screen is used for:

solid, granular, powder, and liquid materials.

Applications:

Food industry – Pharmaceuticals – Glass – Steel – Plastics – Metals.

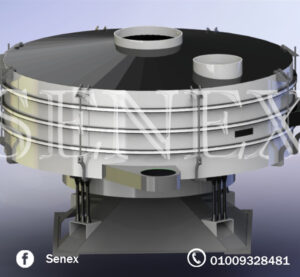

A separation device that uses circular vibrating motion to classify and separate materials by size.

Key Features:

- High screening accuracy

- Suitable for both dry and wet materials

- Compact design and easy maintenance

- High processing capacity

Suitable Materials:

- Fine powders

- Small granules

- Dry or wet materials

Industrial Applications:

- Food industry (sugar, flour, grains)

- Chemical industry (powders and raw materials)

- Pharmaceutical industry

- Mining and minerals

- Plastics and recyclin

Crushers / Grinding Mill

SENEX delivers a comprehensive range of precision-engineered crushing and grinding solutions, incorporating cutting-edge technologies and stringent quality standards to serve diverse industrial sectors.

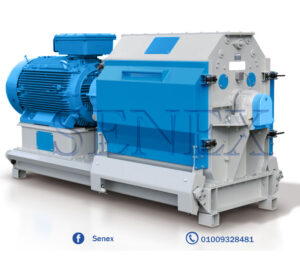

A machine used to grind and break solid materials such as grains, feed, or raw industrial materials into smaller sizes for easier processing or use.

Main Industrial Applications:

- Feed Industry: Grinding grains and corn.

- Wood Industry: Crushing and grinding wood shavings into powder.

- Plastics Industry: Reducing the size of raw materials for easier mixing or processing.

An industrial machine used to crush and grind plastic waste or raw plastic materials into smaller pieces or granules, making them easier for recycling or further processing such as mixing, melting, or molding.

Key Features:

- Reduces the size of bulky plastic materials.

- Facilitates feeding into recycling lines.

- Saves transportation and storage costs.

- Available in different sizes and capacities to fit industrial needs.

Industrial Applications:

- Recycling of used plastics (bottles, containers, packaging).

- Preparing raw plastic materials for molding or extrusion.

- Improving the efficiency of plastic granule production for reuse.

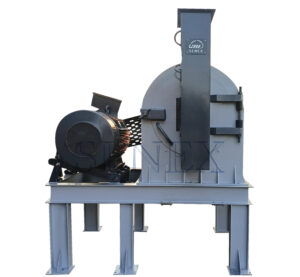

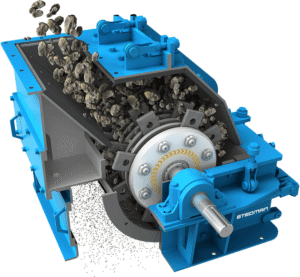

A grinding machine that uses high-speed rotating hammers to crush and grind solid materials into smaller particles. It is widely used in industries that require medium to fine grinding of raw materials.

Key Features:

- High grinding efficiency.

- Suitable for a wide range of materials with different hardness levels.

- Easy operation and maintenance.

- Adjustable particle size through screens.

Industrial Applications:

- Feed Industry: Grinding grains and corn for animal feed.

- Food Industry: Crushing spices and grains.

- Wood Industry: Grinding wood shavings into fine powder.

- Chemical & Plastic Industries: Processing raw materials for easier handling.

An industrial machine designed to grind solid materials into very fine powder, making them easier to use in various industrial applications. It usually operates through friction, pressure, or fine blades/hammers.

Key Features:

- Produces ultra-fine powder with high precision.

- Suitable for a wide range of materials: organic, mineral, or chemical.

- Adjustable fineness according to requirements.

- Available in different sizes and capacities for production lines.

Industrial Applications:

- Food Industry: Grinding sugar, coffee, spices, and grains.

- Pharmaceutical Industry: Producing fine powders for medicines and active ingredients.

- Chemical Industry: Grinding raw materials for chemical production.

- Metallurgy: Converting certain raw minerals into powder for further processing.

Blenders / Mixers Machines

We provide our clients with a comprehensive range of industrial mixing systems, engineered to the highest quality standards and cutting-edge technology to meet the requirements of pharmaceutical, food, and chemical industries:

A high-efficiency mixer designed to achieve homogeneous blending of various materials such as powders, granules, and pastes within a short time of 3 – 7 minutes, featuring fast and easy discharge.

Specifications:

- Material of Construction: Painted steel, Stainless Steel 304, or Stainless Steel 316.

- Production Capacity: Typically ranges from 0.25 ton/hour up to 12 ton/hour or more depending on design.

Key Features:

- Excellent mixing uniformity.

- Short mixing time.

- Fast and efficient discharge.

- Flexible construction materials to suit different applications.

Industrial Applications:

- Food industry.

- Plastic industry.

- Agricultural industry.

- Building materials.

- Pharmaceutical industry.

This mixer works by dividing the product mass and blending it sequentially, creating a fast movement for each particle inside the mixing chamber. It is specially designed to handle and mix highly cohesive materials efficiently and uniformly.

Specifications:

- Material of Construction: Painted steel, Stainless Steel 304, or Stainless Steel 316.

- Production Capacity: Ranges from 0.25 ton/hour up to 15 ton/hour or more depending on design.

Key Features:

- High efficiency in mixing viscous or cohesive materials.

- Excellent homogeneity of the final product.

- Flexible material options to suit various industries.

Industrial Applications:

- Detergent production.

- Pesticide industry.

- Paints and coatings.

- Ceramic industry.

This mixer is designed for blending and mixing dry powders, granules, and crystals with small additive quantities, while maintaining the integrity of the materials without breakage. It is especially suitable for sensitive and low-density products.

Suitable Materials:

- Fine and dry powders.

- Fragile or breakage-sensitive materials.

- Low-density materials.

Industrial Applications:

- Pharmaceutical industry.

- Food industry.

- Chemical industry.

An industrial mixer equipped with a tank and an agitator shaft fitted with rotating blades, designed to ensure efficient mixing and homogenization of liquids and semi-liquids.

Key Features:

- Fast and uniform mixing of various liquids.

- Option to integrate heating or cooling systems for the tank.

- Flexible design suitable for different industrial processes.

Industrial Applications:

- Food industry.

- Pharmaceutical industry.

- Chemical industry.

Material Conveying Systems

SENEX delivers a complete range of engineered material handling systems tailored to diverse industrial requirements – from food and pharmaceutical sectors to construction and mining industries. Our systems incorporate cutting-edge global technologies to ensure high transfer efficiency while maintaining material integrity.

Engineered for high-efficiency bulk material handling, these feeders feature 3–5 mm thick stainless steel U-shaped transfer channels. They are equipped with wear-resistant steel alloy helical blades and offer adjustable transfer speeds (30–60 RPM), ensuring reliable and precise conveying.

Key Features:

- Durable stainless steel construction.

- Wear-resistant helical blades.

- Adjustable speed control (30–60 RPM).

- High efficiency for bulk material transfer.

Applications:

- Food industry.

- Pharmaceutical industry.

- Ideal for conveying dry materials and powders.

These conveyors are designed with a fully enclosed tubular structure to prevent material leakage and ensure environmental cleanliness. Built with stainless steel pipes (100–500 mm diameter) and fully compatible with CIP cleaning systems, they are ideal for handling moisture-sensitive materials or products requiring sterile transfer conditions.

Key Features:

- Fully enclosed design to avoid leakage.

- Stainless steel construction (100–500 mm pipe diameter).

- Compatible with CIP (Clean-in-Place) systems.

- Ensures clean and sterile transfer.

Applications:

- Moisture-sensitive powders.

- Sterile or hygienic material transfer.

- Food, pharmaceutical, and chemical industries.

The ideal solution for food and pharmaceutical industries, featuring non-toxic, antibacterial conveyor belts. Designed for easy cleaning and sterilization, with transport speeds up to 60 meters/minute. Available in various widths from 200-1200 mm.

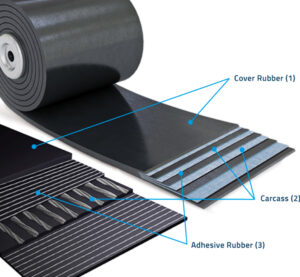

Specifically engineered for abrasive materials in mining and construction industries. Features a heavy-duty 8-12mm thick rubber belt with polyester reinforcement layers, delivering exceptional tear resistance and weatherproof durability.

Blowers

From industrial ventilation to material handling – comprehensive pneumatic solutions meeting global standards.

SENEX high-pressure blowers deliver up to 2.5 bar pressure with airflow capacities reaching 3,000 m³/h. Manufactured from high-strength aluminum alloys and equipped with digital pressure control systems, they are primarily used for pneumatic conveying and industrial vacuum applications.

Other Products

SENEX delivers engineered material handling systems tailored to diverse industrial requirements—from food and pharmaceutical sectors to construction and mining industries. Our systems incorporate cutting-edge global technologies to ensure optimal transfer efficiency while maintaining material integrity.

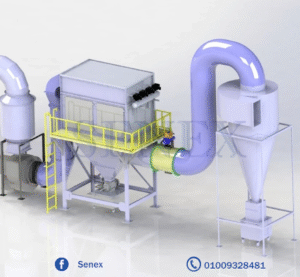

The Dust Collector System is an industrial system used to remove dust and solid particles from the air or gas emitted during production processes in factories. It aims to improve air quality and protect both equipment and workers.

Key Features:

High efficiency in removing dust and fine particles.

Multi-stage filtration system using bag or cartridge filters.

Automatic filter cleaning with compressed air (Pulse Jet Cleaning).

Durable construction suitable for harsh industrial environments.

Low energy consumption and easy maintenance.

Industrial Applications:

Cement and metal industries.

Food and pharmaceutical industries.

Wood and furniture manufacturing.

Paint, chemical, and plastic industries.

Central ventilation systems in factories.

Industrial tanks are containers designed for the storage, mixing, or processing of liquids, chemicals, and other materials used in various production processes.

They are built from durable materials such as stainless steel, carbon steel, or plastic, depending on the type of material stored.

Key Features:

Available in various capacities and shapes (vertical, horizontal, conical bottom, etc.).

Can include agitators, heating or cooling jackets, and insulation layers.

Designed to withstand pressure, corrosion, and temperature variations.

Easy to clean and maintain for hygienic operations.

Industrial Applications:

Food and beverage production.

Pharmaceutical and cosmetic industries.

Chemical and petrochemical plants.

Water treatment and storage systems.

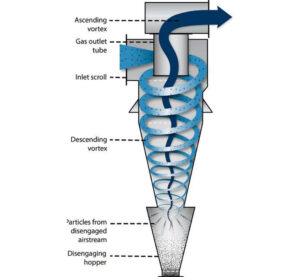

A Rotary Valve, also known as a Rotary Airlock, is a mechanical device used to control the flow of bulk materials (such as powders, granules, or pellets) between two chambers with different pressure levels — usually from a hopper, silo, or cyclone into a conveying or dust collection system.

It helps maintain air pressure while ensuring a consistent material feed.

Key Features:

Precise and continuous material discharge.

Airtight sealing to prevent air leakage.

Suitable for handling dry and free-flowing materials.

Constructed from stainless steel or cast iron for durability.

Easy to disassemble and clean.

Industrial Applications:

Pneumatic conveying systems.

Dust collector discharge systems.

Food and pharmaceutical industries.

Chemical, plastic, and cement processing plants.

Why Choose SENEX?

Extensive expertise in industrial production line design and manufacturing

15 years of excellence in engineering production lines

Specialized engineering team delivering precise customized solutions

High-quality products meeting global standards (ISO, CE, ASME)

Genuine warranties with professional after-sales service

Innovative technologies ensuring higher efficiency and lower operational costs

Comprehensive technical support (installation, maintenance, spare parts, training)

Milestones That Make The Difference

At SENEX, we take pride in our track record of successful projects that reflect our engineering expertise. These achievements aren’t just numbers – they’re success stories woven in collaboration with our valued clients.

SINEX Doesn't Just Deliver Products - We Build Decades-Long Trust!

Contact Us Today for the Support You Deserve!

✓ Free Engineering Consultations from Industry Experts

✓ Competitive & Fast Quotations

✓ Customized Solutions for Your Business Needs

Or leave your message and we'll respond promptly.